Fiberglass is a fiber-reinforced plastic made from fiberglass. Fiberglass is additionally understood as fiberglass-strengthened plastic or fiberglass-reinforced plastic .

Fiberglass is extremely solid, adaptable as well as lightweight. Fiberglass can be formed into several intricate forms, making it a superbly lightweight material structure product. Fiberglass is commonly used in tubs, watercraft, aircraft, roofing systems, and other insulation materials in a wide range of applications.

The world's leading glass fiber manufacturers, such as China Jushi Group, Owens Corning, Nippon Electric Glass Co., Ltd., and many other well-known manufacturers, have established a complete glass fiber industry chain.

Today Heaterk will take you to an in-depth understanding of glass fiber from all aspects of the glass fiber industry.

Fiberglass dust, characterized by its delicate, powdery texture, typically exhibits a white or light gray hue. Despite its diminutive size, it can become visible when present in significant quantities or when disturbed, causing it to disperse into the air. Handling fiberglass demands utmost caution to prevent inhalation of this dust, as it potentially harms the respiratory system.

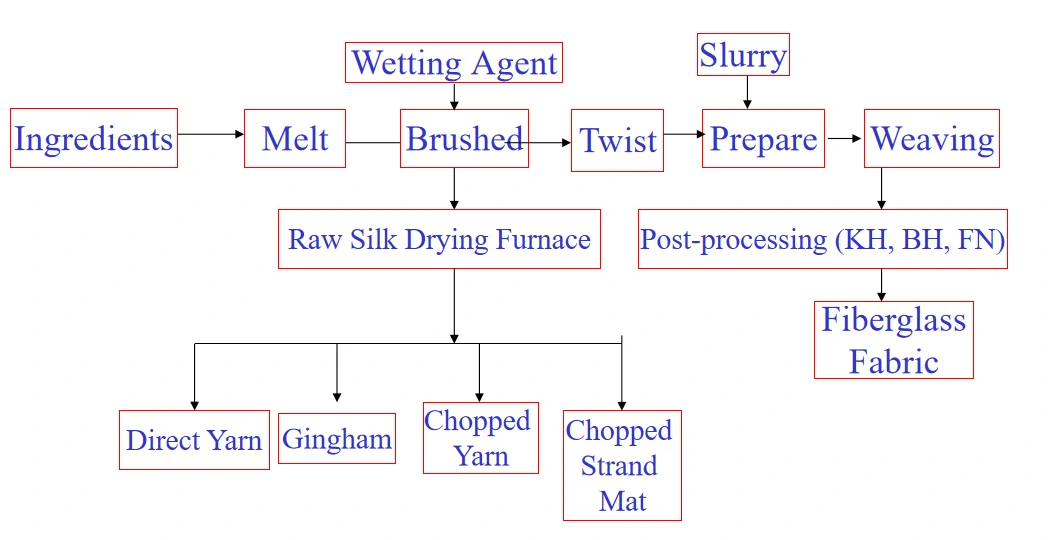

The following processes are involved in the production of heat-resistant glass products. The raw ore is melted through a high-temperature furnace, and the obtained high-temperature slurry is formed into filamentous fibers through the wire drawing process.

After multiple molten glass manufacturing processes, the raw molten glass materials from glass filaments can be flattened into a sheet glass fiber cloth, glass wool composite material, aluminum foil composite glass fiber fabric, etc.

Fiberglass is produced through various manufacturing processes, including:

Hand Lay-up: In this process, fiberglass and resin sheets are manually applied to reusable molds with a hardener. The mold is coated with a release agent to prevent the fiberglass from adhering. Fiberglass mats are stacked until the desired thickness is achieved, followed by a curing process to ensure the product maintains its strength. Glass tape can reinforce the mold's edges during the hand lay-up process.

Spray-up: This method involves spraying resin and fiberglass onto the mold-like hand lay-up. Workers then use rollers to compress the material, ensuring proper compaction. After allowing the mold to cure, the finished product is removed from the reusable mold .

Compression Molding: In this technique, a sheet molding compound consisting of long fiberglass sheets is laid on a bed of polyester or epoxy and placed over a heated mold within a machine. The machine then applies downward force, enveloping the compound around the heated mold. This process is widely used for manufacturing cold water storage tanks, low-cost structures, electrical applications such as meter boxes, and high-volume production in the automotive and transportation sectors.

1. Fiberglass production batching - preparing and mixing various powders according to the proportion of the process standard.

2. The fiberglass raw materials used are: pyrophyllite , calcite , boro site , silica sand , mirabilite , fluorite (soda ash, carbon powder)

Fiberglass is a non-conductive material. This key property makes fiberglass an excellent choice for applications requiring electrical insulation. Whether in construction, manufacturing, or other industries, fiberglass's non-conductive nature helps prevent the flow of electricity, enhance safety and reducing the risk of electrical accidents. Understanding that fiberglass is non-conductive can guide informed decisions in selecting materials for projects where electrical conductivity is a concern.

E: Good electrical insulation properties

C: Chemical resistance, corrosion resistance

A: High content of alkali metal oxides

D: Good dielectric properties

S or R: High strength

M: High elastic friction

AR: Alkali Resistant

E-CR: Good insulating properties and chemical resistance

AE: This glass fiber has excellent alkali resistance characteristics and is specially used in concrete

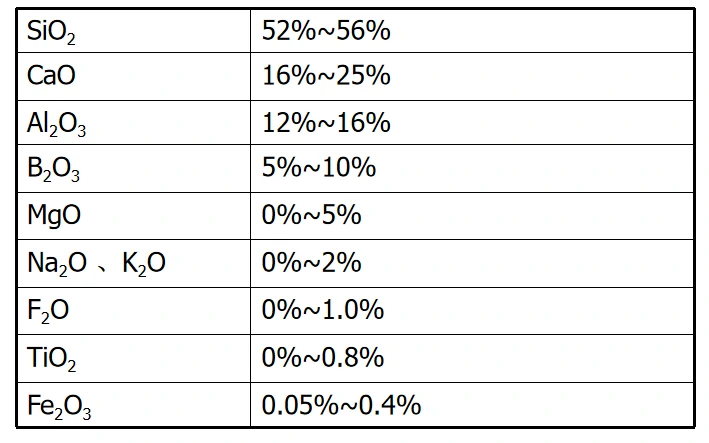

1. Refers to the composition of alumino-borosilicate glass with an alkali metal (potassium and sodium) oxide content of less than 1% , usually called "E" glass internationally. "E" glass composition basis mainly includes SiO2, Al2O3, and CaO three-element systems.

Melting - is to put the prepared and mixed batch materials into the pool kiln and melt them into glass liquid at high temperature.

The melting point of fiberglass refers to the temperature at which the material transitions from a solid state to a molten, liquid state. This property is crucial for determining the suitability of fiberglass for various high-temperature applications, such as thermal insulation in the automotive, aerospace, and construction industries.

The melting point of fiberglass can be influenced by several factors, including the types of glass fibers used, the manufacturing process, and the presence of additives or coatings. These factors can lead to variations in the melting point, impacting the material's performance under high- temperature conditions.

Fiberglass is primarily composed of silica (SiO2) in the form of silicon atoms, which form a network bonded at the corners by sharing the oxygen atoms. Other components, such as alumina (Al2O3), boron oxide (B2O3), and calcium oxide ( CaO), can also be present in the type of glass used. The composition of the glass fibers directly affects the melting point. For example, E-glass fibers, which are predominantly composed of silica and alumina, have a melting point of approximately 1550 °C (2822°F).

The method used to manufacture fiberglass can impact its melting point. For example, the rotary process involves a rotating spinner and, due to centrifugal force, spins molten glass into extremely fine fibers of glass with small diameters suitable for textile processing. This process typically produces fiberglass with a slightly lower melting point compared to the flame attenuation process, where glass fibers are drawn from a molten glass stream using high-velocity air or steam.

Additives and coatings can be incorporated into fiberglass to enhance its properties, such as heat resistance or chemical resistance. However, these additives can also affect the melting point of the material. It's essential to consider the potential impact of additives on the melting point when selecting fiberglass for high-temperature applications.

Furnace Melting Point section fuel: 80# heavy oil

1. Space temperature: 1550-1560℃

2. Glass temperature: 1440-1450℃

Furnace Pass Fuel: LPG

1. Space temperature: 1310-1330℃

2. Glass temperature: 1270-1300℃

The softening point, a related property, refers to the temperature at which glass flows and is extruded into many fibers. This property is also essential in determining the material's suitability for specific applications.

The high ratio of surface area to weight (50 of surface area to weight) contributes to fiberglass's excellent insulating properties. However, humidity is an important factor in the tensile strength of fiberglass, as moisture can affect the material's performance.

What is the number of strands (Tex): the grams per kilometer g/Km.

The glass fiber drawing process is a fundamental aspect of optical fiber manufacturing and the production of other high-quality glass fibers. This highly specialized technique involves the delicate balance of heat transfer, draw tension, and precise control of gas flow, including argon gas, to create fibers with exceptional properties. In this introduction, we will explore the key elements of the glass fiber drawing process, emphasizing the significance of computational studies, radiative heat, and the role of the draw furnace in ensuring the production of top-tier fibers .

At the core of the glass fiber drawing process lies the draw furnace, a high-temperature heating device designed to maintain consistent heat transfer and radiative heat conditions. This carefully regulated environment facilitates the controlled melting of the glass preform, allowing it to be drawn into a neck-down profile with high speed and precision.

During the drawing process, the gas flow, often consisting of argon gas, plays a critical role in protecting the glass fiber from contamination and ensuring an even temperature distribution. This gas flow management is essential for maintaining the structural integrity and quality of the fibers being produced.

11111111111111111

Top 5 Heat-Resistant Wonders: How High Silica Fiberglass Fabric Excels in Extreme Temperatures!

Top 5 Heat-Resistant Wonders: How High Silica Fiberglass Fabric Excels in Extreme Temperatures!

Is Kevlar Fireproof? Unveiling the Truth Behind Kevlar's Flame Resistance

Is Kevlar Fireproof? Unveiling the Truth Behind Kevlar's Flame Resistance

Do Fire Blankets Work? Understanding Their Functionality and Benefits

Do Fire Blankets Work? Understanding Their Functionality and Benefits

2023, Heaterk's Year-End Recognition Meeting!

2023, Heaterk's Year-End Recognition Meeting!